This is the story of a guy from India who used to tinker with Royal Enfields in his native country, then moved to the United States in 1999 where he takes a job as a teacher in industrial design at an Art and Design College. In 2003 he imports an old Enfield engine and begins to fantasize on building his own engine using only standard Enfield parts and keeping it as simple as the original Bullet engine is.

This is the story of a guy from India who used to tinker with Royal Enfields in his native country, then moved to the United States in 1999 where he takes a job as a teacher in industrial design at an Art and Design College. In 2003 he imports an old Enfield engine and begins to fantasize on building his own engine using only standard Enfield parts and keeping it as simple as the original Bullet engine is.

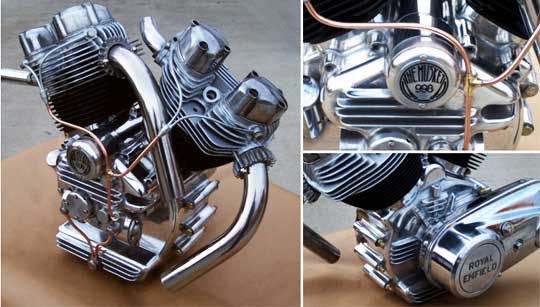

On weekends, he starts building patterns, then ends up quitting his job to fully dedicate himself to his V-Twin project. Took him one year to learn machining, then two years more of design development, detail refinement before painstakingly fabricating all the new casting patterns, After doing a 700 cc version, he went to a bigger size and completed the first 998cc Musket V-Twin in December 2012.

This is the first 998cc Musket, using the 500 Bullet top ends. It’s quite a beautiful and a very smooth looking engine. It features a 59-degree V angle, keeps all Bullet internal parts, gets copper oil pipes for a true vintage look.

This is the first 998cc Musket, using the 500 Bullet top ends. It’s quite a beautiful and a very smooth looking engine. It features a 59-degree V angle, keeps all Bullet internal parts, gets copper oil pipes for a true vintage look.

This new motor has been installed into the frame of a test machine – a 2002 Bullet 500 – and a full specific frame chassis is now being conceived for it.

Aesthetically very pleasing, it could be the power plant of many custom projects. Below is the video of the first 998 cc Musket V-Twin engine start-up. Sounds very good…

That is a sweet looking engine.

Looks good, it would probably run alot better with some exhaust on it.

What’s this guys name?

Great looking motor Needs some frame design to eliminate the curve in the front downtube should be a winner

LenNY Sinnet

Roscoe… his name is Aniket Vardhan: What a great story! I have been following him for years…

Wet sump?

Very cool. Great workings. Sounds good too. Thanx !

The gearbox looks Berman or British – and I bet with low motor rpm’s it’s a smooth shifter too.

What he’s saying is….. “We want to turn you on!”.

That is beautiful! The external oil lines look really good too!

I’ll bet the custom community could fix that frame downtube in short order. I couldn’t even imagine the amount of work that went into this man’s education and then into his engine. Wow, very impressive!

This is a very good looking engine but with the exhaust on the back head coming forward instead of backward it will be interesting to see how he incorporates the rest of the the pipes to make it flow both pleasing to the eye and performance.

Cyril. What a great find. Would love to get engine #2 for a new custom project. will contact this genius.

Very exciting. Beautiful motor.

Thanks Domino.

This guy represents the American Dream.

Another immigrant doing better than Americans… Without new immigrants America is dead.

The rear header could be Y-ed into the front header in front of the crankcase and then have one exhaust pipe and then enlarge the one pipe from 1-1/2 to 2″ to the muffler. Or, after the Y, move the oil sump lines away from the motor more and “float” the single exhaust tube through the open space along the crankcase (above the fins of oil sump), then enlarge the pipe to a 2″ single with a 20″ cigar muffler after it bends under, around, and exits mid-transmission.

That is commitment right there! peace

Admirable!

@ Dragon Bob

There are a few ways to do the exhaust; just look at a Vincent Shadow, Rapide or Lightning.

In fact Phil Irving (Vincent Engineer) got the idea to build a (998cc) V-Twin after he saw two blueprints of (499cc) single engines laying on top of each other. As with this Enfield the parts from the single were used to make the twin. That was 1946 I think, but takes nothing away from this excellent effort. Well done!

This motor is so beautiful it makes me ache! If I could see one of these used in a Falcon Motorcycles creation, I think I could die in peace.

Very cool story, and a good looking engine… it will be interesting to see what comes of this. I wish him well.

Very cool looking motor. Once he gets all the bugs worked out and has a proper frame designed to compliment the lines of the motor, he shold have a winner. Best of luck to him!

Very very nice. Looking forward to seeing it progress into a few bikes.

Knock, knock. It’s the EPA and we would like to see you paperwork.

He’s got a video of the 700cc twin he built, it’s in a modified elongated Bullet 500. The video on his website shows him driving it, sound is great. The guy is definitely resourceful.

When he carved the first set of wooden blanks to be cast, (a very long difficult process)the forge guy left the blanks on a window sill where they got rained on, swelled up and were ruined. I think that would have finished a lesser man.

Under 24 engines can be built for show bikes and not be EPA approved. Just must apply for a waiver. Carb will not allow. If engine is clean enough. Full cert program is not overly expensive for for both EPA and Euro3 complyance.

congrats, looks like a winner.keep up the great ideas

1 Royal Enfeild is 18 HP and 2 is 36 Hp. 1 drive on I-95 with that 1000 cc Engine and you will hate Life.

Love it! put it in a longer lower frame, and its a winner. Have Bert Baker massage the trans, and it’ll be fine on I-95.

Yeah, I-95 in CT.

This will probably hit the market before the new Indian…………………..

Holy Giant Elephants!

Did my project actually get featured by *Cyril Huze* ??????

Am I dreaming? Are the pixels playing devious tricks with my mind?

Must check…where’s my curry powder….slap into the eyeballs….OWWWW!

Wow. It’s still here.

Well, THANK YOU Cyril and everyone who has posted such encouraging comments! Thank you thank you thank you, this means very much to me.

Now, a bit about that frame mod, heh heh. You see, the whole plot was designed to be able to fit into a stock Bullet frame with the minimum hassle for the simplest route to a classic Brit V-twin, without the atmospheric pricetag of such rare machines as Vincents and Broughs and Matchlesses. The stock Bullet frame with the top tube cut and stretched and the downtube untouched, does allow for a simple way to get it in there but the stretch required is around 6″….this results in a wheelbase of around 60″, which is pretty much the same as a Sportster. This is exactly what I did for the first bike- the 700. With the new motor, I could have gone the same route but wanted to try getting the wheelbase as short as possible for a quick turning, nippy, light, britbike feel. Hence the curved downtube which makes room for that front cylinder and allows a wheelbase of 56.5″, which is just 1″ more than a Vincent.

Highway wise, I haven’t taken this one out yet, it’s snowed up here in Columbus but the old 700 was surprisingly smooth and cruised very comfortably at 65mph,thanks to the bigger output sprocket keeping the revs down 25%. The wider V angle certainly seems to help in reducing the vibes.

If you guys would like to see plenty pics of the build process and machining and whatnot, please do check out the facebook page for “the musket v twin”.

Many thanks and a Happy New Year to all of you.

Aniket

Some fantastic and inspirational work Aniket!

Now there is a Guy willing to work at his dream, a true ” Product Champion “, (:-)

And u can purchase one of these at any 7-11 with a fill up

The Enfield single is a sweet-running engine capable of remarkably good fuel economy. I reckon this is why the design has survived so long. This excellent project has great potential for development . If the present Bullet can be improved to meet EPA, then so can this. Congratulations. Inspiring

Now your talking true “custom built” stuff.

Very cool.

RE:

“…The gearbox looks Berman or British…”

-No-

That would be an Albion gear box complete with neutral-finder.

And no, this not a wet sump. Like the Interceptor, a separate sump is cast into the lower end.

Take a good look at the oil pump, it has both a feed and a scavenge side.

-nicker-

Dear Aniket,

Great Work.

I have always been true bike lover, in fact i have seen your V Twin many times through internet the more i see the more i want to hear musket sound. The sound specially is awesome. Great going.

Shaji C

Indore

Madhya Pradesh

India